Electro-Mechanical Assembly, Box Build & UL 508A Control Panels

Custom turnkey electronic box, unit, and control panel manufacture—from product development, DFM and DFx, NPI, through to all phases of fully scalable global production—we’ve got you covered.

Custom turnkey electronic box, unit, and control panel manufacture—from product development, DFM and DFx, NPI, through to all phases of fully scalable global production—we’ve got you covered.

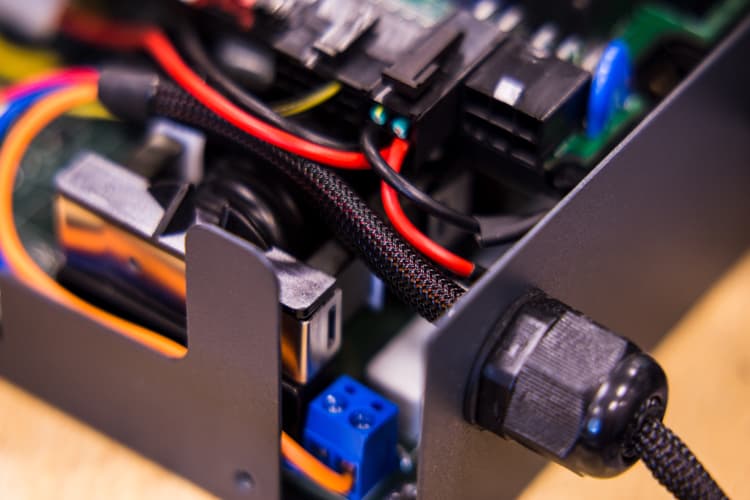

These complex products often involve expertly integrating IP-rated enclosures; panels; PCBAs; controls; passive, active, and electro-mechanical components; pneumatics; and connectivity (wiring, cabling, fiber optics, and connectorization). Our distinguished manufacturing partners produce your fully configured, tested, and IP-rated products, with emphasis on quality, efficiency, and automation.

The right strategic certifications, UL 508A, S20.20 ESD compliance, firmware/software installation, and comprehensive validation and functional testing capabilities ensure compliance with all of your specifications. Applications include:

- Medical devices

- Robotics

- Industrial electronic enclosures & panels

- Power trays

- Control & test boxes

- HVAC controls

- Aerospace, defense & commercial aviation

- Transportation

- Renewable energy

- IoT devices

- Telecom

- Semiconductor

- Computer & storage

- Instrumentation

- Homeland Security

Electro-Mechanical Assemblies,

Box Builds & Control Panels

A Deep Dive Resource for OEMs

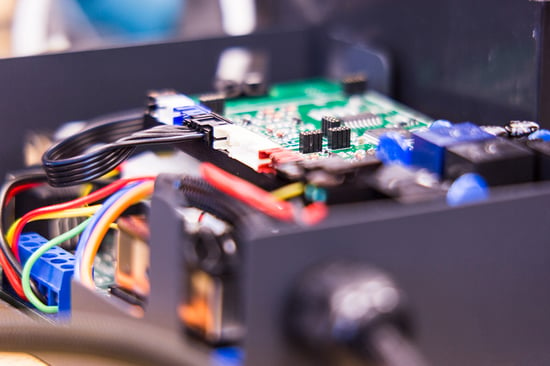

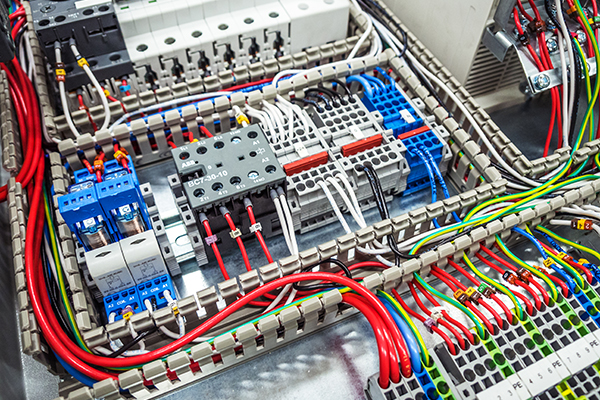

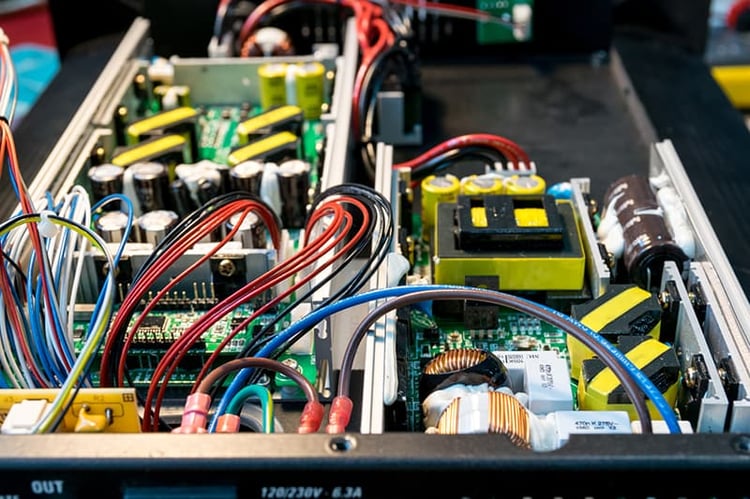

Electro-mechanical assemblies, box builds, and control panels are at the heart of today’s most advanced products, powering innovation and functionality across industries from medical devices and industrial automation to consumer electronics. These solutions seamlessly integrate electronic and mechanical components—such as PCBAs, power supplies, fans, gauges, switches, sensors, heat sinks, displays, motors, and custom connectivity—often housed within robust IP-rated enclosures to deliver reliable, high-performance systems tailored to demanding applications.

Agility Tech and its strategic partners specialize in providing expert DFM and engineering support, optimizing, and manufacturing complex turnkey electro-mechanical assemblies, box builds, and control panels. Our end-to-end capabilities ensure every assembly meets rigorous standards for quality, functionality, efficiency, and scalability. From precise power management and advanced automation to intuitive user interfaces, installation of firmware/software, and comprehensive testing, our integrated approach enhances the overall design and manufacturability, eliminates down-time, accelerates production, and simplifies maintenance.

This resource page explores the essential components, assembly processes, and advantages of electro-mechanical and box build integration. Whether you’re seeking to streamline your supply chain, enhance product reliability, or accelerate time-to-market, you’ll find actionable insights and proven strategies for success in today’s competitive manufacturing landscape.

You can view the discussion in its entirety or click on any of the topics below to be taken directly to that portion of the page.

Electro-Mechanical Assemblies and Box Build Integration

Electro-mechanical assemblies are essential to modern technology, combining electrical and mechanical components for reliable, high-performance solutions. We specialize in the support and manufacture of these complex systems to the highest standards, delivering measurable value to our customers.

Agility Tech and its strategic partners are equipped to reduce your total cost through our concerted efficiency-centric approach. We can help you achieve enhanced reliability and will support your objectives and initiatives through our following attributes and core competencies, no matter your industry or application:

- Requisite certifications (ISO 9001, ISO 13485, UL/CSA, IPC, ITAR, C-TPAT)

- Expert DFM

- Evaluation of BOMs for accuracy and compatibility

- Alternate component expertise

- Development of logical sub-assembly hierarchy

- Expert documentation services

- Commitment to QMS excellence

- Tooling expertise

- Supply chain proficiency and execution

- Prototyping and new product introduction (NPI) services

- Fully scalable production

- Advanced automation

- ERP/MRP proficiency

- Tariff and customs management & optimization

- Logistics support

What Is Box Build Assembly?

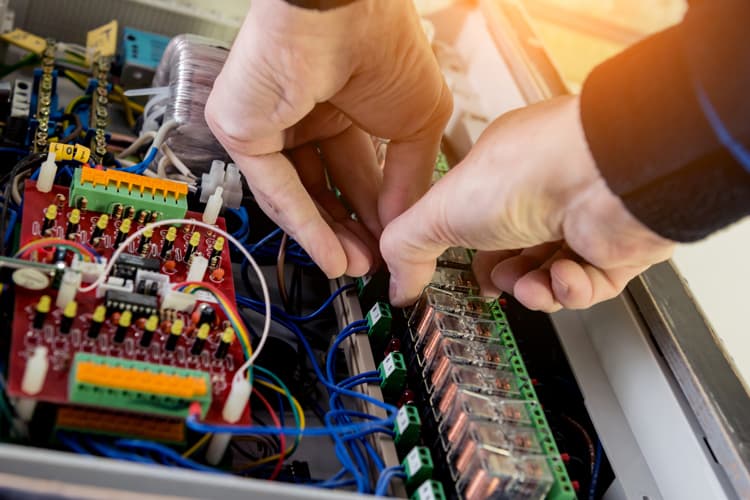

Electro-mechanical assembly and box build—also known as system integration—takes the integration process to its logical conclusion, creating a fully realized and functional product to serve infinite applications.

Electro-mechanical assembly and box build—also known as system integration—takes the integration process to its logical conclusion, creating a fully realized and functional product to serve infinite applications.

It involves assembling and interconnecting all required components into a complete, operational product housed within a protective enclosure or chassis, or assembled onto a panel for additional functionality and system integration.

This process goes well beyond the manufacture of various singular sub-assemblies, encompassing everything from installing circuit boards, wire harnesses and cable assemblies, to integrating power supplies, displays, electro-mechanical devices, such as switches, sensors and gauges. It often requires firmware/software installation, burn-in, environmental and functional testing and validation, ensuring that the final product is delivered fully configured and functional, ready-to-use, reducing setup time for the customer and ensuring reliable field performance.

We’re happy to begin a conversation with you about your EMS requirements at any time. Contact us today so we can explore which of our vast capabilities best suits your needs.

Common Contents

| Item | Description | Function |

|---|---|---|

| Enclosure/Chassis | Durable housing for all components | Protects electronics; ensures long product life |

| PCB Assemblies | Central electronic control and connectivity | Compact, high-functionality solutions |

| Fans | Device for movement of air | Air circulation, ventilation, and cooling |

| Connectivity | Streamlined, reliable internal ad external wiring/cabling | Faster assembly, eliminates point-to-point wiring errors |

| Power Supplies | Safe, efficient power distribution | Consistent reliable source of required power & performance |

| Displays & Interfaces | User control and feedback | Easy operation and monitoring |

| Mechanical Components | Heat sinks, brackets, etc. for cooling, mounting, etc. | Prevents overheating, boosts reliability, provide mounting features |

| Firmware/Software Installation | Uploading and configuring system firmware/software for system operation | Products arrive ready-to-use |

| Labeling & Packaging | Compliance and traceability | Simplifies inventory tracking, provides required serialization, protects assembly during shipment |

| Testing & QA | Functional and environmental validation | Ensures proper operation and reliable field performance |

Why Choose Box Build Integration?

- Integrated functionality: Provides highest level of integrated functionality, convenience, and serviceability within a single assembly

- Precision & Consistency: Automated, repeatable manufacturing processes for enhanced quality and reliability

- Lower Costs: Streamlined assembly and supply chain leverage reduce expenses

- Faster Time to Market: Optimized workflows speed up delivery

- Expertise & Flexibility: Access to skilled engineers; DFM, prototyping & NPI support; scalable production solutions

- Compliance & Safety: Rigorous quality control, meets industry standards

- Resource Optimization: Free up your team while we handle sourcing, manufacturing, and logistics

- Supply Chain Efficiency: Fewer suppliers to manage; choose an EMS partner who can support your current and future DFM, prototyping, NPI & scalable production, just-in-time delivery & fulfillment needs

- Enhanced Performance: Integrated testing and validation ensure reliability in the field

At Agility Tech, our box build solutions simplify your sourcing efforts, cut costs, and get your products to market faster—without compromising quality or compliance. For more discussion about electro-mechanical assembly and box build and the direct benefits to customers, check out this article.

Agility Tech’s EMS & Box Build Capabilities

End-to-End Services

Agility Tech delivers a comprehensive suite of synergistic vertical integration and electro-mechanical assembly and box build solutions designed to streamline your product lifecycle from concept through to realization and shipment.

Design for Manufacturing (DFM) & Prototyping: Our engineering experts collaborate with you early in the process, providing DFM services, tooling and automation assessments, rapid prototyping, and design-for-excellence (DFx) support to optimize manufacturability, efficiency, testing methodology, and serviceability.

PCB Assembly, Cable Harnesses, & Subsystem Integration: We offer advanced high-speed PCB assembly; custom cable assembly, wire harnesses, and fiber optics fabrication; design and manufacture of custom power supplies; injection molded plastics & low pressure molding along with tooling support; metal injection molding; precision metal fabrication & machining; and seamless integration of electro-mechanical sub-assemblies and box build—providing our customers with strategic advantage in the marketplace, ensuring robust, reliable performance.

Final Assembly & Testing: Agility Tech manages the entire box build process, including mechanical and electrical assembly, connectivity, firmware/software installation, burn-in, and environmental and functional testing and validation. Our teams ensure every product is delivered fully tested, compliant, and ready for deployment.

Requisite Certifications & Standards

We maintain rigorous quality management systems and protocols, and meet or exceed required industry certifications, including:

- ISO 9001

- ISO 13485 (medical device)

- IPC (requirements and standards for electronic assembly and cable assemblies/wire harnesses)

- ITAR (International Traffic in Arms Regulations)—safeguarding U.S. security and restricting access to sensitive military technologies

- C-TPAT (Customs-Trade Partnership Against Terrorism)—Enhancement of international supply chain security

- UL/CSA RoHS, and REACH compliance

Advanced Technologies

Agility Tech and its partners invest in the latest manufacturing technologies and automation to ensure efficiency, precision, repeatability, and scalability. Electro-mechanical and box build manufacturing share similarities and are often considered the same capability-set in the industry. For a great overview, we explore their similarities and differences in this article.

For a look at seven crucial steps involved in electro-mechanical and box build manufacturing of high-quality, reliable products, we explore them here.

We’re happy to begin a conversation with you about your box build requirements at any time. Contact us today so we can explore which of our vast capabilities best suits your needs.

Multi-Site Manufacturing Advantage

Geographic Advantage & Flexibility

With strategically located facilities in the U.S., Mexico, and offshore, Agility Tech optimizes logistics, lead-times, and tariff exposure for every project.

Tariff Mitigation Strategies

- Cost Localization: We source materials and components regionally and assemble products close to end markets, reducing import duties and shipping costs.

- Dutiable Value Optimization: Agility Tech helps U.S. customers recover the highest possible customs duties, taxes, and fees on imported goods that are later exported, destroyed, or used in products for export, helping them stay competitive in the global market. For a deeper discussion, see this article we posted on navigating tariffs.

- Duty Drawback & FTZ Utilization: We leverage free trade zones and duty recovery programs to further reduce landed costs.

Scalability & Risk Mitigation

- Dual- and multi-sourcing capabilities and strategies avoid single-point failures and ensure business continuity.

- Dedicated work cells support both high-mix/low-volume and high-volume production, allowing rapid scaling as your needs evolve.

Industries & Applications

Industries & Applications

Agility Tech’s box build solutions serve a wide range of industries, each with unique compliance and performance requirements. Here are a few notable industries we serve (see our extensive industry portfolio here):

- Medical Devices: FDA-compliant assemblies for diagnostic equipment, surgical aids, and patient monitoring systems.

- Industrial Automation: Control panels, motor drives, sensor arrays, and robotics assemblies.

- Consumer Electronics: IoT devices, smart home systems, wearables, and connected appliances.

Supply Chain & Tariff Resilience

Integrated Supply Chain Management

Agility Tech’s global sourcing team manages component procurement, kitting, and vendor-managed inventory (VMI) programs, all tracked in real-time.

We deliver supply chain agility and resilience through a globally diversified supplier network and vertically integrated operations. By leveraging real-time monitoring, flexible sourcing, and dynamic scenario planning, we rapidly adapt to shifting tariffs and trade policies. Our proactive, tech-driven approach enables swift recalibration of production and logistics, empowering customers to anticipate risks, avoid costly delays, and maintain business continuity in today’s volatile global market.

We ensure continuity of supply, minimize shortages, and optimize inventory levels across all manufacturing sites.

Tariff-Smart Structuring

Our engineering teams work closely with clients to optimize product design and sourcing strategies, identifying alternative components and qualifying for more favorable tariff classifications without sacrificing quality or speed. We further support our customers by advising on optimal Harmonized Schedule (HS) codes and utilizing free trade zones (FTZs) to minimize duties, streamline inventory management, and reduce overall tariff exposure.

We design customer-centric strategies that strengthen your bottom line. Through cost stability initiatives like strategic supplier contracts, bulk purchasing, and duty drawback recovery, we help clients control expenses and reclaim customs fees. Our responsive North American and offshore operations accelerate time-to-market, while localized engineering support ensures rapid design iterations and seamless project coordination—delivering measurable value and operational stability where it matters most.

For a detailed discussion on how we handle tariff turbulence, you'll find it here.

We’re happy to begin a conversation with you about your EMS and box build requirements at any time. Contact us today so we can explore which of our vast capabilities best suits your needs.

Bill of Material (BOM) Accuracy

Managing bills of materials (BOMs) is one of the most critical aspects of bringing electro-mechanical products to market. For OEMs, even small errors or inefficiencies in BOM management can lead to costly delays, excess inventory, or quality issues. That’s why many leading OEMs are turning to EMS partners for electro-mechanical assembly and box build. By leveraging the expertise, systems, and supply chain strength of a qualified EMS provider, OEMs can streamline BOM management, reduce costs, and ensure reliable, high-quality production—freeing their teams to focus on innovation and core business goals. Here’s how a qualified EMS partner can transform your approach to BOM management and deliver measurable value throughout the product lifecycle.

How EMS Partners Help OEMs Manage BOMs

1. Validation of BOM Accuracy

A qualified EMS partner can validate accuracy of specified BOM components and verify compatibility thereof for the intended use during a comprehensive DFM review. An integral part of this DFM effort is to:

- Verify that the specified components are suitable for production automation tooling

- Verify component lead times and MOQs

- Identify any EOL (end-of-life) concerns and put a contingency plan in place for any problem components

- Determine shelf life and safe storage conditions, such as temperature and humidity

2. Purchasing Expertise and Supply Chain Leverage

EMS providers typically take on the responsibility of sourcing and purchasing all BOM components for turnkey products—including high-value semiconductors and commodity parts—using their long-established supplier relationships, agreements, and purchasing power. This consolidation allows OEMs to benefit from better pricing, reduced MOQs/MRQs, preventing counterfeit parts from entering the supply chain, and consistently reliable access to quality materials. By aggregating material and component orders across multiple customers and projects, EMS firms can negotiate more favorable terms with suppliers, which translates to cost savings for OEMs.

3. Inventory Reduction and Cost Savings

When EMS partners manage the BOM, OEMs no longer need to maintain large inventories, purchasing staff can be reallocated, reducing overhead and freeing up capital. The EMS provider’s expertise in forecasting and inventory management facilitates component availability when needed on a JIT basis, minimizing production delays and excess stock.

4. Real-Time BOM Management and Collaboration

Modern EMS partners use advanced BOM management tools and ERP/MRP, providing real-time visibility into inventory levels, part status, and component availability. This transparency enables efficient communication between engineering, purchasing, and manufacturing, accelerating the design-to-production cycle.

5. Streamlined Production and Error Prevention

A well-managed, accurate BOM—overseen by the EMS partner—helps get products into production faster while eliminating errors. The EMS partner’s experience with BOMs, CAD models, assembly documentation, DFM support, automation and tooling, and prototyping ensures all necessary details are captured, tested, and validated before full-scale manufacturing begins.

6. Quality, Testing, and Compliance

EMS providers often integrate rigorous quality control and testing throughout the build process. This means BOM items are not only sourced and assembled correctly, but can also be coded in ERP to undergo incoming inspection to ensure compliance with industry specifications, reducing the risk of rework, field failures, and costly recalls.

7. Scalability and Flexibility

Qualified EMS partners can quickly scale production, adapt to demand spikes, and manage multi-level BOMs for complex assemblies. Their infrastructure and expertise allow OEMs to efficiently transition from prototype stage to full production without a hitch.

We’re happy to begin a conversation with you about your EMS and box build requirements at any time—the sooner in the engagement, the better. Contact us today so we can explore which of our vast capabilities best suits your needs.

Let’s Summarize: EMS Partner BOM Management Advantages to OEMs

| Benefit | How Qualified EMS Partners Deliver Tangible Value |

|---|---|

| Cost Savings | Supply chain proficiency/management, leveraging existing automation & tooling and alternate component open stocks, reduced inventory. |

| Supply Chain Resilience | Vetted suppliers, strategic sourcing, leveraging existing EMS partner supply-chain relationships and agreements, counterfeit avoidance |

|

Accelerated Time-to Market |

Advanced real-time ERP/MRP tools, fast procurement, streamlined communication |

| Quality & Compliance | Integrated in-process and functional testing, consistent workmanship, regulatory expertise |

| Flexibility & Scalability | Rapid response to demand changes, multi-level BOM management |

| Error Detection | Accurate, centralized BOM management and documentation |

Having an EMS partner manage your BOM means lower costs, faster production, higher quality, and less risk for OEMs. By leveraging the EMS partner’s purchasing expertise, supply chain strength, and advanced BOM management tools, OEMs can focus on innovation and growth while their manufacturing partner ensures efficient, reliable, and compliant product delivery. To continue the BOM discussion, check out our articles about BOM basics, and one that provides a great checklist for working with EMS partners, and understanding the importance of comprehensive BOMs when outsourcing with an EMS partner.

Our Partnership Ethos

At Agility Tech, we believe that successful partnerships are built on a foundation of clear communication, mutual respect, and a shared commitment to excellence. Our Partnership Ethos checklist embodies these principles, guiding OEMs to collaborate effectively beyond the basics. By embracing this ethos, both parties can optimize design, streamline production, manage risks, and drive innovation and excellence together, ensuring superior quality, cost efficiency, and faster time-to-market. This checklist serves as a roadmap to foster transparency, agility, and continuous improvement throughout every stage of the electro-mechanical assembly and box build journey.

1. Establish Clear Communication Channels

Set up regular meetings, define points of contact, and agree on communication protocols to ensure updates and issues are addressed promptly.

2. Share Complete and Accurate Documentation

Provide a thorough BOM (with alternates), CAD files, assembly drawings, and test requirements. This eliminates errors and streamlines production.

3. Prioritize Design for Manufacturability (DFM)

Choose an EMS partner whose skillset includes reviewing your designs and BOMs for accuracy, manufacturability, and automation & tooling suitability— suggesting improvements and implementing automation to reduce costs and accelerate time-to-market.

4. Align on Technical Capabilities and Certifications

Verify that your EMS provider’s technical skills, requisite certifications (ISO, IPC, UL/CSA, ITAR, C-TPAT, etc.), and processes align with your current and future company, product, and industry requirements.

5. Collaborate on Supply Chain Strategy

Leverage your EMS partner’s supplier networks for better pricing, lead times, and terms. Clarify inventory ownership and discuss risk mitigation plans for shortages or disruptions.

6. Plan for Change Management

Establish clear protocols for handling engineering change orders (ECOs) and documentation updates. Involve your EMS partner early in new product introduction (NPI) for valuable input and smoother ramp-up.

7. Focus on Quality and Compliance

Ensure your EMS partner has robust quality management systems, in-process and final testing, and the necessary certifications to meet your current and future needs and objectives.

8. Build in Flexibility and Risk Management

Discuss how your EMS partner handles demand swings, scalability, and crisis response for supply chain or BOM issues.

9. Evaluate Total Cost and Value

Look beyond unit price—consider responsiveness, commitment to excellence across all facets of business, lead times, supply chain management, quality, and the EMS partner’s ability to reduce your internal costs and accelerate time-to-market, not just for your current needs, but for your future needs as well.

10. Foster a Collaborative, Problem-Solving Culture

Choose a partner who is proactive, eager to innovate, and committed to continuous improvement and mutual success.

These principles allow us to foster robust partnerships that go far beyond basic product handoff—enabling collaborative DFM, cost reduction initiatives, smoother launches, enhanced quality, and greater resilience in today’s dynamic manufacturing environment.

Choosing Agility Tech

We exploit our multi-site agility, ensuring business continuity and effective cost control. Through leveraging our strategic supply chain relationships, bundled sourcing, our advanced automation and production capabilities and inter-operational coordination and cooperation across global sites, we achieve economies of scale, delivering significant cost savings compared to single-site manufacturing models. Quality assurance is realized through our ongoing commitment to and maintenance of requisite certifications, QMS excellence, standardized processes and dedicated quality control, which ensures consistent results, regardless of production location. Additionally, Agility Tech is committed to sustainability, employing lean manufacturing practices and regional sourcing to reduce waste and carbon footprint, proudly supporting the Environmental, Social, and Governance (ESG) goals of our customers.

Proven commitment and execution:

- Multi-Site Agility

- Automation

- Cost Efficiency

- Quality Assurance

- Synergistic Vertical Integration

- Sustainability

- BOM Management

- Tariff Resiliency

Why Agility Tech

Custom turnkey electro-mechanical assembly, electronic box, unit, and UL508A control panel manufacture—from product development, DFM and DFx, NPI, through to all phases of fully scalable global production—we’ve got you covered. Our adherence to the right strategic certifications, ISO 9001, ISO 13485, UL/CSA, UL508A, IPC, J-STD-001 Soldering, RoHS and Reach compliance, and S20.20 ESD compliance, firmware/software installation, and comprehensive validation and functional testing capabilities ensure compliance with all of your specifications.

Contact us today to discuss your EMS requirements. As you can see, we have vast capabilities and can efficiently meet your needs.

Agility Tech – Where Challenges Become Solutions