WHAT WE DO

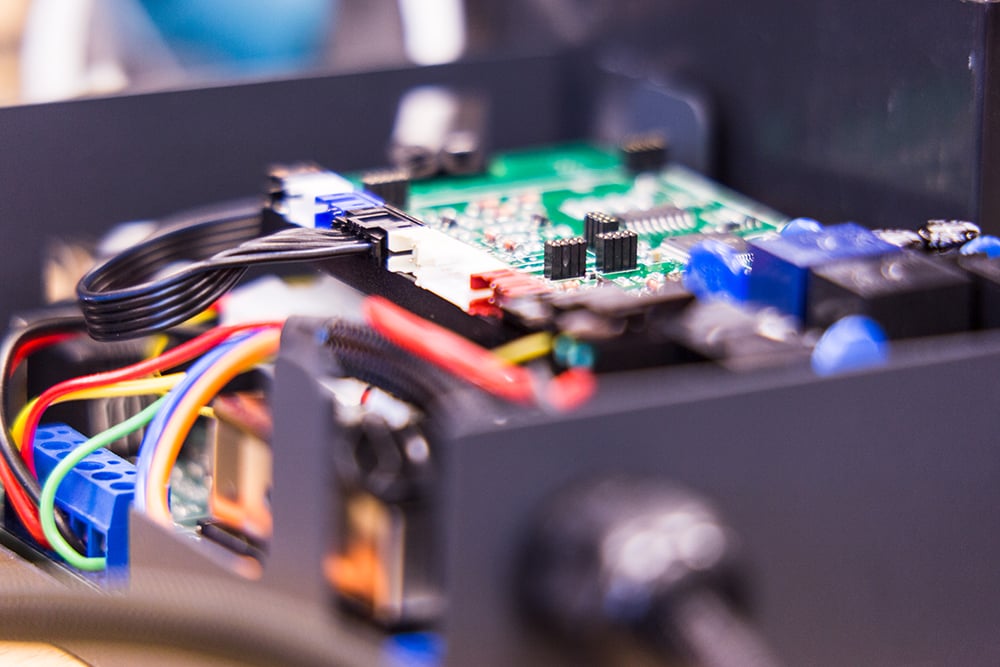

Agility Tech provides an all-inclusive and synergistic offering of expert global electronic manufacturing capabilities and services, which include:

- A comprehensive range of interconnect expertise & capabilities

- Fiber optic assemblies

- Electro-mechanical assembly, control panels, box- & unit-build

- Bare PCB, Flex, Semi-Flex & Rigid-Flex

- Printed circuit board assembly

- Standard & custom power supply solutions

- Injection Molded Plastics & Low Pressure Molding

- Precision metal fabrication & machining

We guide you through the product development cycle, providing valuable design assistance and global manufacturing insight. We subject all the products we manufacture to a comprehensive Design-for-Excellence (DFx) review early-on in our project engagement. The first step in this DFx process involves an overarching design-for-manufacturability assessment, followed by scrutinizing all supply chain and other relevant factors, such as testing compliance, possible future upgrades, and serviceability. We then quickly transition your project to fully scalable turnkey production (domestically, in Nogales, Mexico, or off-shore) to meet your specific objectives.

Design for Manufacturability (DFM)

- Compatibility verification of specified components, and suitability for intended application and functionality

- Alternate materials/components support as circumstances require

- Verification of RoHS compliance and support of other applicable regulatory requirements

- Development of sub-assembly hierarchy for optimal operator comprehension, manufacturing processing & efficiency, testing methodology, and overall quality

- Compatibility with automated manufacturing processes & equipment

Design for Supply Chain (DFSC)

Supply chain strategies of the past aren’t just obsolete—they simply do not work in today's global environment. The impacts that the pandemic and cyber security concerns have had on supply chain approach and logistics, once thought to be temporary, have brought about many problematic changes and obstacles—some of which are likely here to stay, at least for the foreseeable future:

- Global workforce shortage

- Decline of materials availability, global supply chain dependability, and quality of goods and services

- Component obsolescence & lead-times outside demand—necessitating alternate component expertise/support

- The need for more powerful integrated ERP tools to ensure transparency in the tracking, monitoring, and management of inventory and pipeline goods throughout the entire global supply chain

- Safety stock and pipeline management for long-lead-time materials and components

- Cyber security threats and IP risk mitigation

- Ideological and regulatory shifts specific to sustainability and social responsibility initiatives, and ongoing validation of supplier synergy, culture, diversity and workforce welfare, and health measures

Agility Tech and its strategic global manufacturing partners thoroughly understand these challenges and obstacles, and are successfully navigating this new normal with preemptive supply chain infrastructure and methodology.

DFSC Services

Today’s manufacturing, supply chain, and sourcing environment is complex and highly challenging. Agility Tech provides trusted insight and deploys strategic global manufacturing models (U.S., Mexico, and Off-Shore) to meet your specific project NPI, time-to-market, total cost, quality, service, production scalability, and tailored fulfillment objectives.

Agility Tech and our strategic supply partners are committed, highly capable, resourceful, flexible, and resilient. Together, we provide tactical optimization of your manufacturing and support model, materials and components sourcing strategies, and accelerated execution and realization of required production tooling.

Our DFSC Strategy Encompasses:

- Ongoing adherence to customer-specified materials/components

- Quality

- Cost optimization

- Mitigation of and contingency planning for long lead-time and EOL materials

- Traceability

- Logistics optimization

We Mitigate & Manage Your Risk:

- Anticipated shortages/stock-outs

- Down-stream supply chain interruptions

- Component EOL (end of life), obsolescence and possible alternates

- IP protection

- ESD (electrostatic discharge) protocol

- Prevention of counterfeit materials entering the supply chain

- Environmental considerations (humidity, temperature)

- Shelf life

- Logistics management

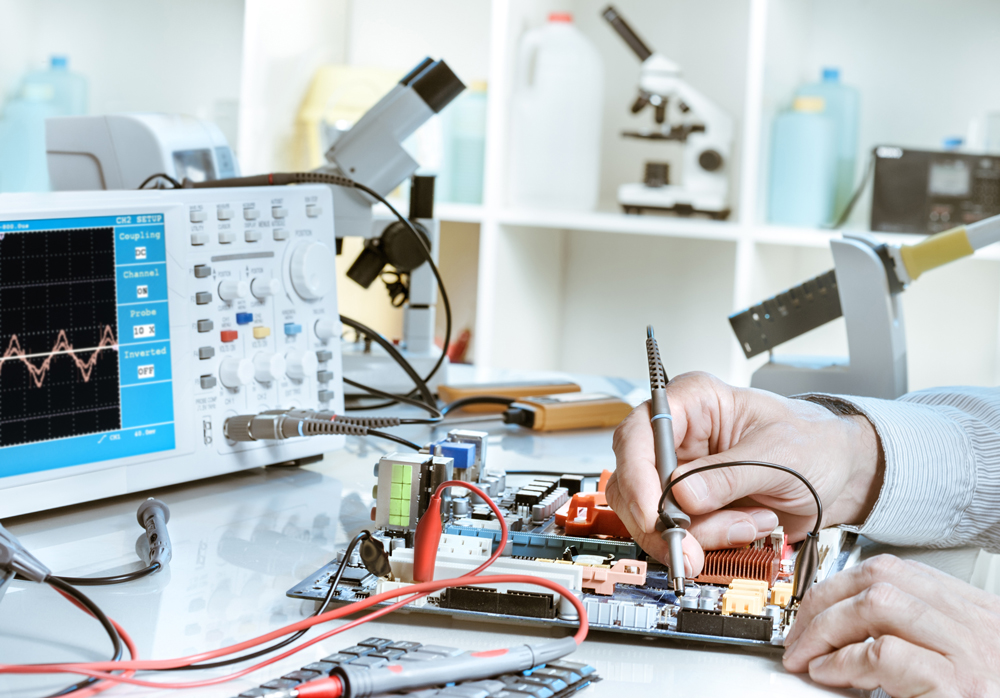

Design for Test (DFT)

We determine specific testing necessary to ensure compliance with your requirements, and we structure the manufacturing processes to efficiently implement the required testing for each product we manufacture:

- Development of test strategies

- Sub-assembly testing

- In-process & final testing/validation

- Point-to-point continuity testing

- Hipot testing

- Technician/multi-meter testing

- Firmware installation and validation

- Functional testing

- Optical crimp inspection

Design for Upgrades (DFU)

Preemptive product and associated tooling design—to accommodate possible future upgrades/configurations, and emerging product families, in a concerted effort to enhance product synergy and economy of scale, and maximize ROI (return on investment)

Design for Serviceability (DFS)

Ensuring that products are designed to be functionally and economically serviceable

Commitment to Sustainability Principles

Agility Tech is committed to the preservation of our shared environment and planet, social awareness, responsibility, and stewardship, as are our global manufacturing partners. We continue to collectively employ methods to decrease fossil fuel dependance and our combined carbon footprint by making the best use of natural resources and implementing innovative methods of decreasing consumption across all facets of our collective operations; we practice sustainability stewardship locally and globally.

How can we help you with your next electronic manufacturing services project? Contact us today and we'll explore the possibilities.