MANUFACTURING SERVICES

Design for Excellence (DFx)

From assessing the market and gauging resources to design and proof of concept, and the many other factors involved in executing a successful NPI, having Agility Tech in your corner as your trusted advisor is a strategic advantage. With decades of valuable expertise in product launches, we guide you through the many aspects that encompass a successful and timely new product introduction (NPI).

From assessing the market and gauging resources to design and proof of concept, and the many other factors involved in executing a successful NPI, having Agility Tech in your corner as your trusted advisor is a strategic advantage. With decades of valuable expertise in product launches, we guide you through the many aspects that encompass a successful and timely new product introduction (NPI).

This includes:

- Navigating design

- DFM and DFx

- Process and automation optimization

- Assessment of applicable regulatory requirements

- Determination and realization of testing requirements

- Development of comprehensive process documentation

- Provision of 3D evaluation models

- Design and manufacture of production mold tooling

- Scaling global manufacturing to meet demand

- Managing the BOM and supply chain

- Realization/implementation of custom OEM packaging and kitting requirements

- Optimization of global logistics

- Assurance that all specifications and requirements are met, and the highest quality standards achieved

Total-Cost Optimization

Focusing on material cost and order volume alone doesn’t come close to addressing all aspects that contribute to total cost. Some cost variables are tangible: material, labor, overhead, exchange rates, among them. The less quantifiable factors, such as poor quality, manufacturing inefficiency, scrap, cost of tooling, excess inventory, long lead-times, high MOQs that exceed demand, obsolescence, logistics, and missed delivery deadlines, along with many other potential issues, all contribute to your total cost.

As experts at anticipating and adapting to change and obstacles, and developing comprehensive strategies that assess and realize your needs, we work with you to achieve the manufacturing solutions that meet your goals and objectives.

Design for Manufacturing & Assembly

With so many options available for manufacturing and assembly outsourcing, you need assurance that you are entrusting the right manufacturing partner with your valued business and success. Agility Tech’s Design-for-Excellence (DFx) review begins from the moment you engage us. We guide you through the product development cycle, providing valuable design assistance and global manufacturing insight.

DFx review includes:

- Design for manufacturability (DFM)

- Design for supply chain (DFSP)

- Design for test (DFT)

- Design for upgrades (DFU)

- Design for serviceability (DFS)

- Design for compliance (DFC)

DFM review includes:

- Compatibility verification of specified components, and suitability for intended application and functionality

- Alternate materials/components support as circumstances require

- Verification of RoHS compliance and support of other applicable regulatory requirements

- Development of intelligent sub-assembly hierarchy

- Compatibility with automated manufacturing processes

- Assessment and optimization of manufacturing efficiency and overall quality

Contact us today to discuss your EMS requirements. As you can see, we have vast manufacturing services available

to you and can efficiently meet your needs.

Supply Chain Optimization

Today’s global manufacturing and electronic component sourcing environment is dynamic and complex, and requires systems, strategies, and contingencies in place to urgently identify, navigate, and address anomalies and obstacles as they arise.

Agility Tech and its strategic global manufacturing partners thoroughly understand these challenges and obstacles, and are prepared with preemptive supply chain sensibility, infrastructure, and methodology to sustain a robust, effective, reliable, and resilient supply chain.

North America Manufacturing

New England (USA)

Nogales, Mexico

Founded in 1986, with unrelenting focus on quality, automation, efficiency, service, and QMS excellence, augmented by its extensive certifications, domestic and Mexico presence, our North America partner is equipped to competitively and reliably manufacture your products:

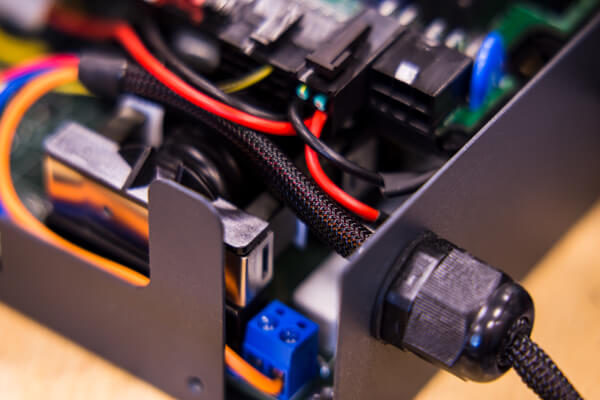

- Turnkey electro-mechanical/electronic box and unit build/control panels

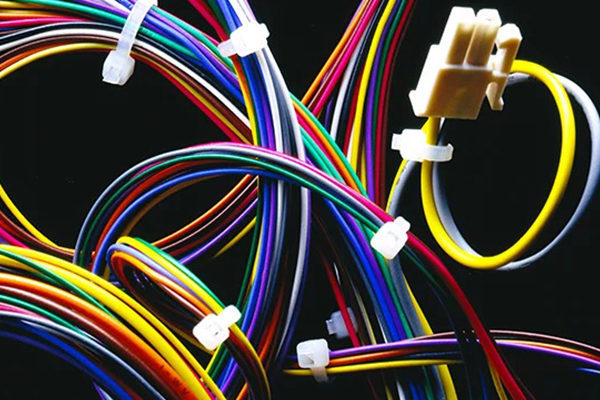

- Custom cable assemblies

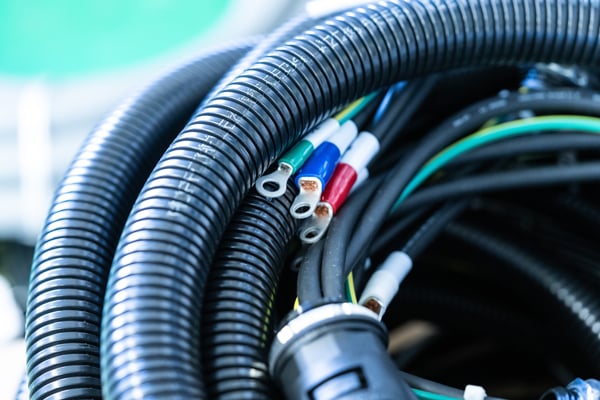

- Complex wire harnesses

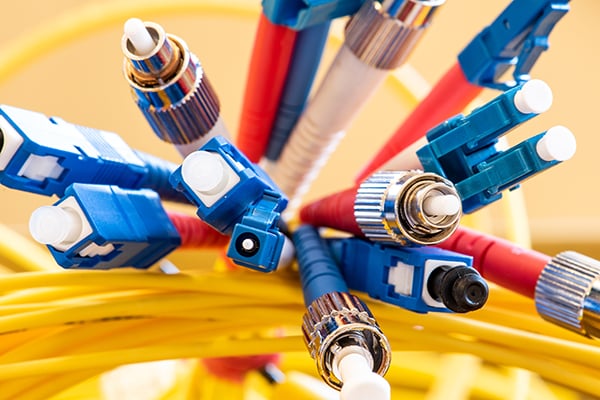

- Fiber optic assemblies

- Potted assemblies

- Kitting

We offer integrated world-class manufacturing facilities in New England, USA (40,000 square feet) and Nogales, Mexico (35,000 square feet), with industry-leading, state-of-the-art automation and DFM capabilities.

ITAR │ C-TPAT │ RoHS & Reach Compliance │ S20.20 ESD Compliant

Off-Shore Manufacturing

Agility Tech's off-shore manufacturing operations offer a total of 129,000+ square feet in a highly strategic low-cost region, and is ISO 9001, ISO 13485 Medical Device, ISO 45001 Occupational Health & Safety, ISO 14001 Environmental Management System, and UL/CSA certified. With extensive synergistic vertical integration capabilities, we deliver convenience, confidence, distinguished support, and the highest quality products:

- Custom cable assemblies of all varieties

- Molded cable assemblies with tooling design and manufacture support

- Low pressure molding

- Complex wire harnesses

- Electro-mechanical assemblies

- Electronic box and unit builds

- Injection molded plastics with tooling design & manufacture support

- Printed circuit board assembly (medium- and high-speed SMT lines)

- Custom power supplies

- Potted assemblies

- Coil cords

- Kitting & custom OEM packaging

Contact us today to discuss your EMS requirements. As you can see, we have vast manufacturing services available

to you and can efficiently meet your needs.