Off-Shore Manufacturing

Established in 1994, Agility Tech’s off-shore EMS operations are strategically vertically integrated and we deliver the highest quality products with capabilities that include:

- Electro-mechanical assemblies

- Electronic box & unit builds

- Custom cables

- Custom-molded cable assemblies with tooling design & manufacture support

- Complex wire harnesses

- RF-coaxial cable assemblies

- Ribbon cables & coil cords

- Low-pressure molding

- Injection molded plastics with tooling design & manufacture support

- Potted assemblies

-

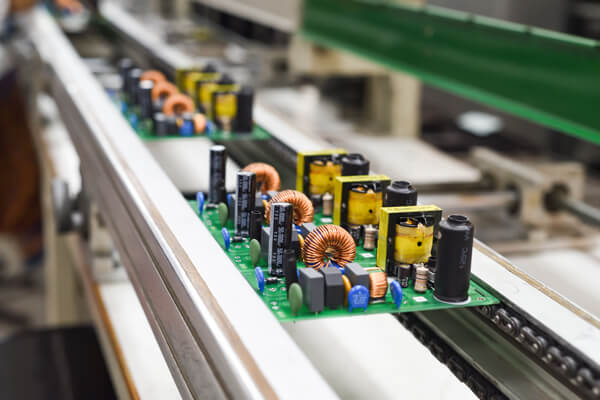

Printed circuit board assembly (medium- & high-speed lines)

-

Custom power supplies

- Kitting & custom OEM packaging

Custom Cables, Molded Cables, Complex Wire Harnesses, Electro-Mechanical Assembly & Unit Build

Located in a highly strategic low-cost region, we offer 129,000+ square feet and the following certifications:

ISO 9001 │ ISO 13485 Medical Device │ ISO 45001 Occupational Health & Safety │

ISO 14001 Environmental Management System │ UL/CSA │CE │CCC │MET │TUV

- Automated crimping presses

- 100% automated fail-safe continuity testing

- Functional testing

- Hipot testing

- High-productivity, fully automatic wire processing—cutting, stripping, tinning, crimping

- Optical crimp inspection

- Automated rotary stripping machines

- Extreme precision laser stripping

- Wire inkjet printing

- Hose cutting machines

- Industrial ovens and mandrel fixtures for coil cord manufacture

Molded Cable Assemblies

- High-quality molded cable assemblies of all types, constructions, and complexities

- Custom molded connectors, strain-reliefs, ferrites, break-outs, etc.

- Standard and custom retention hardware

- Single stage and pre-mold/over-mold; shielded and non-shielded

- Molded-in custom logos, designations, and nomenclature

- Low pressure molding

- Accelerated mold tooling design and manufacture

Injection Molded Plastics

- Expert injection mold tooling design support

- Quick-turn injection mold production tooling

- Highly competitive tooling and part pricing

- Multitude of compounds and colors

- Volume flexibility

- In-house injection molding machines up to 140 tons, with access to larger off-site machines, as required

Printed Circuit Board Assembly

We are equipped with the following capabilities to expertly and competitively support your PCBA needs:

- Medium- and high-speed SMT lines

- Solder paste inspection

- Stuffing

- Wave soldering

- Automatic optical inspection

- In-circuit test

- Auto-test

- Burn-in

- Value-add assembly & kitting

- Firmware installation

- Final/functional testing

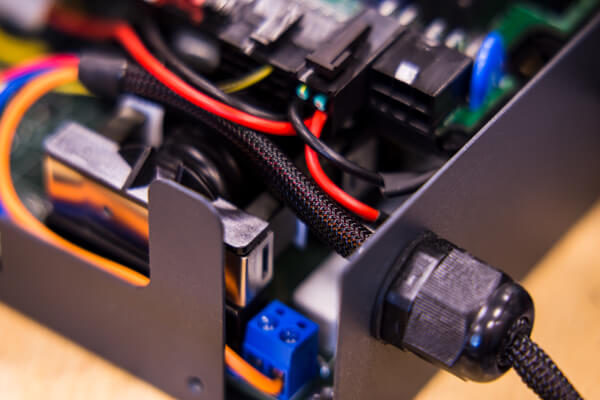

Custom Power Supply Solutions:

Our team of engineers will engage with you and quickly design your custom power supply / charger solutions to achieve your exacting application requirements, specifications and certifications, while meeting your qualification and time-to-market objectives.

- Switching Mode PSU’s:

- AC/DC (10W - 2.5KW)

- DC/AC & AC/AC (100W - 5KW)

- DC/DC (10W - 1500W)

- Multiple Outputs

- In-House PCBA Design & Manufacture

- In-House Magnetic Device Design & Manufacture

- Open Frame & Enclosed Varieties

- Custom Metal and Plastic Enclosures

- Custom Wire Harnesses and Molded Cables

- Additional In-House Capabilities:

- Conformal Coating

- Vibration Testing

- Temp/Humidity Chamber Testing

- Salt Spray Testing