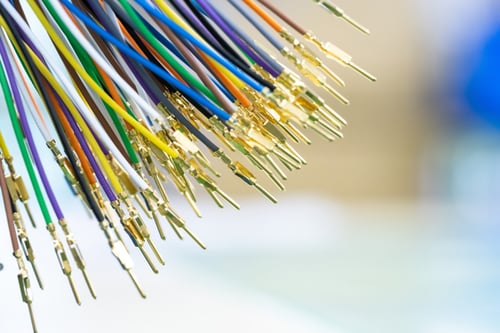

State-of-the-Art Wire & Cable Processing, Crimping, and Labeling

North America

State-of-the-art automation results in increased efficiency, throughput, and capacity. Our distinguished North America operations are equipped with world-class, high-productivity, fully automatic wire processing and termination, automated labeling, bar code, logo and nomenclature imprinting, precision rotary stripping, automated crimping, and crimp quality monitoring capabilities. We offer a multitude of crimp applicators for highly reliable processing and termination of a wide range of industry-standard terminals and contacts in conjunction with best-in-class crimp height monitoring and validation methodology throughout.

Automated Crimping With Crimp Quality Monitoring.

Fully Automatic Wire & Cable Cutting, Stripping, Labeling and Reeling

High-Productivity Fully Automatic Wire Processing & Crimping

Fully Programmable High-Precision Stripping/Crimping

Off-Shore

Agility Tech's highly capable Off-Shore operations are equipped with fully automated high-productivity wire processing, crimping, and tinning equipment, along with in-house extreme-precision laser stripping capabilities for challenging dielectrics and very small wire sizes found in technologically advanced products, such as mobile phones, microwave assemblies, pacemaker coils, medical electrodes, cardiac monitors, and other medical devices. This technology is also ideal for “precise window stripping” (removing insulation or jacket sections of any specified length along a contiguous wire or cable) without damaging or fraying underlying conductors and shields.

Contact us today to discuss your EMS requirements. As you can see, we have vast capabilities and can efficiently meet your needs.