Fiber Optic Assembly Capabilities

Precision, Partnership, and Performance for OEMs

Fiber optic assemblies are at the heart of today’s most demanding applications—from scientific instruments and medical devices to telecom, defense, and industrial automation. As a trusted manufacturing partner, Agility Tech delivers technical excellence along with collaborative support and supply chain reliability that OEMs need to innovate, scale confidently, and meet commitments.

Fiber optic assemblies are at the heart of today’s most demanding applications—from scientific instruments and medical devices to telecom, defense, and industrial automation. As a trusted manufacturing partner, Agility Tech delivers technical excellence along with collaborative support and supply chain reliability that OEMs need to innovate, scale confidently, and meet commitments.

Agility Tech’s North America operations have been leading the way in solutions-focused electronic manufacturing services for well over three decades.

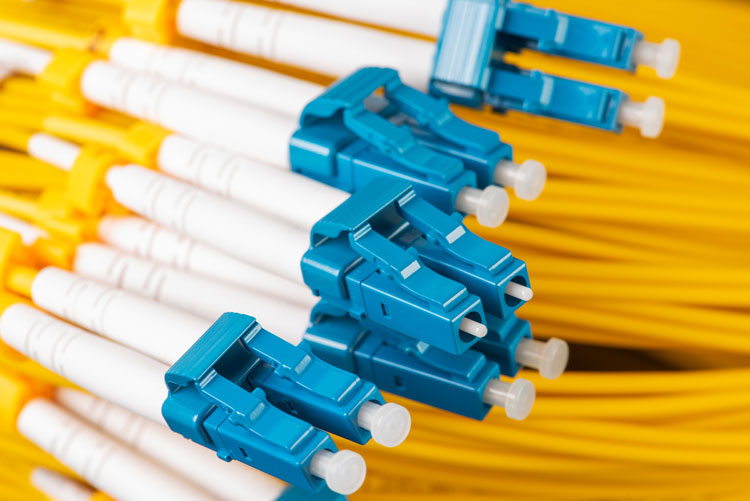

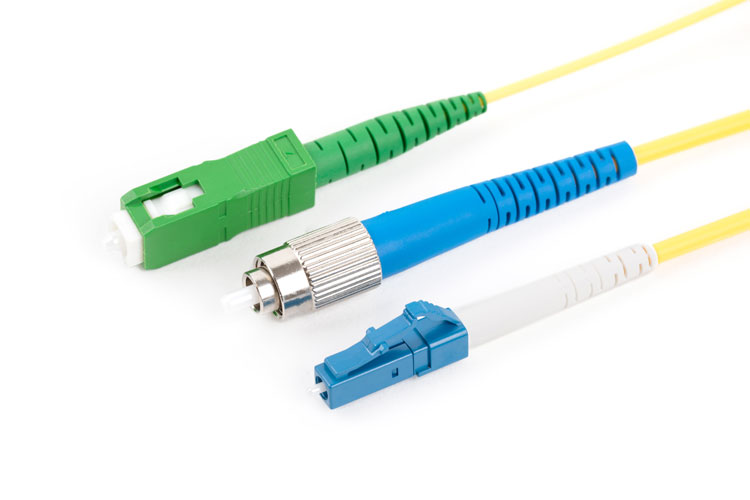

Equipped with in-house glass and plastic fiber optic assembly processing, polishing, assembly, and testing capabilities, our North America operations can expertly support your fiber optic needs, ranging from standard FC and ST configurations and ribbon fiber, to small form factor connection configurations and custom applications.

Click here to learn more about fiber optic basics, our fiber optic capabilities, and how to choose the right manufacturing partner.

Our Fiber Optic Assembly Expertise

With decades of diverse solutions-focused EMS and fiber optic experience, we offer comprehensive fiber optic capabilities to meet the most demanding requirements. Our in-house capabilities include:

- Glass and Plastic Fiber Processing: Precision cutting, stripping, cleaving, and end-face polishing for both single-mode and multimode fibers.

- Connectorization—Standard and custom terminal options include:

- 905 SMA

- 905 SMA ceramic nose

- 905 SMA high-power

- 905 SMA with heat sink

- LC, SC, ST, FC, MPO/MTP

- Small Form Factor

- Rectangular and round slit

- Round ferrule and step

- V-groove slit

- Custom configurations

- Polishing: Initial, intermediate and final precision polishing is critical in the manufacture of fiber optic assemblies, removing excess epoxy, achieving the correct end-face angle/geometry, shaping the ferrule, removing end-face imperfections and scratches that can contribute to signal degradation.

-

Inspection/Cleaning: Industry standards such as IEC 61300-3-35 set stringent criteria for end-face cleanliness and quality, specifying acceptable levels for surface imperfections and contamination.

- Inspection of end-face quality and cleanliness is another crucial step in the manufacture of fiber optic assemblies. Contamination, imperfections or damage (scratches, pits, cracks, debris) can cause significant insertion loss. Even tiny particles can disrupt signal transmission.

- Proper end-face geometry (angle of polish, radius of curvature, apex offset, fiber protrusion) is also essential to ensure proper physical contact and alignment of fiber cores to respective connectors, which is vital to achieving optimal signal transmission.

- When using MPO/MTP connectors, another important parameter is “coplanarity,” which refers to the flatness of the fiber array critical for ensuring uniform contact across all fibers in the connector.

- Digital inspection scopes are used to visually inspect end faces. Automated inspection systems can be used to analyze end-face surfaces and provide a pass or fail, reducing human fatigue/error, further improving efficiency.

- Fiber optic cable assembly manufacturers can significantly improve the reliability, performance, and longevity of their fiber optic cable assemblies by ensuring the proper geometry, quality, and cleanliness of their end faces.

- Testing: Insertion/return loss, Optical Time Domain Reflectometer (OTDR), and environmental validation.

- Compliance: From ribbon fiber and small form factor assemblies to complex multi-fiber and polarization solutions, we build and validate all assemblies to meet stringent performance requirements and withstand rigorous deployment and environmental demands.

Take a look at our blog that discusses what matters most for OEMs when considering fiber optic assemblies.

Some of Our Applications & Markets Served

- Scientific Instruments: Precision fiber assemblies for spectroscopy, chromatography, and laboratory automation.

- Medical Devices: Biocompatible, high-reliability assemblies for imaging, diagnostics, and surgical systems.

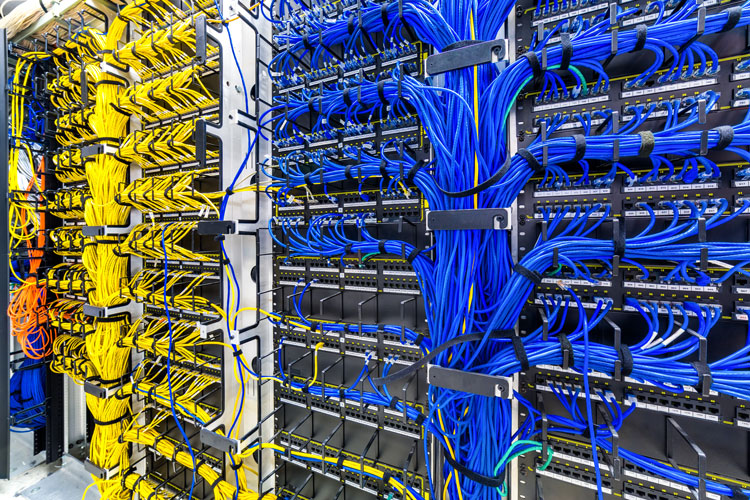

- Telecom & Data Centers: High-density, low-loss solutions for networking, switching, and backbone infrastructure.

- Industrial Automation & Sensing: Ruggedized assemblies for harsh environments and real-time monitoring.

- Defense & Aerospace: Mission-critical fiber optic solutions meeting stringent military and aerospace standards.

OEM Outsourcing of Fiber Optic Products

Outsourcing fiber optic production to a specialized manufacturing partner reduces production risks for OEMs by leveraging expertise, infrastructure and capital equipment/assets, supply chain proficiency, and economies of scale. Below is a concise breakdown of how this approach mitigates key risks:

1. Mitigating Technical & Quality Risks

Precision & Expertise:

Fiber optic production requires specialized expertise, carefully monitored and executed manufacturing and quality control protocols, precision polishing, sub-micron alignment, meticulous cleaning, and complex test/validation equipment. We utilize advanced equipment and highly skilled technicians to produce fiber optic assemblies that meet all customer requirements.

Rigorous Testing:

End-to-end testing is required to ensure compliant fiber optic assemblies, preventing field failures and costly recalls:

- Digital Inspection Scopes: These devices are used to examine the end faces for cleanliness and defects, such as scratches that can degrade signal transmission.

- Insertion Loss (IL) Testing: Measures the signal strength loss as light travels through fiber optic components. A lower insertion loss indicates better performance. Testing with a light source and power meter or an Optical Loss Test Set (OLTS) is a highly accurate method for measuring attenuation or end-to-end signal loss. By analyzing how waves combine and interact, interferometry can be used to measure distances, surface profiles, refractive index variations, etc., with high accuracy.

- Return Loss (RL) Testing: Evaluates the amount of light reflected back towards the source. Higher return loss values signify less reflection, and therefore, better performance.

- Optical Time Domain Reflectometer (OTDR) Testing: An OTDR analyzes reflected and backscattered light to detect faults, bends, splice losses, and measures fiber length.

- Visible Light Source Testing: Using a visible light laser is a method of identifying breaks or bends by showing light leakage.

2. Supply Chain & Component Risks

Component Sourcing: Qualified manufacturing partners manage complex supply chains for connectors, ferrules, specialty fibers and other required components and materials, mitigating shortages and obsolescence through strategic supplier networks.

Component Sourcing: Qualified manufacturing partners manage complex supply chains for connectors, ferrules, specialty fibers and other required components and materials, mitigating shortages and obsolescence through strategic supplier networks.

Multi-Site Manufacturing & Tariff/Logistics Flexibility: Unlike manufacturers limited to a single plant or region, Agility Tech offers multiple synergistic manufacturing operations across strategic regions (U.S., Mexico, and off-shore), with the same requisite certifications, core competencies, and capabilities. This structure allows us to provide our customers with essential manufacturing, engineering, tooling, global supply chain, scalability, and logistics options, leveraging the regions with the most favorable tariff conditions, trade agreements between cooperating countries, and logistics as circumstances dictate. Agility Tech offers its customers essential flexibility and options—quickly adapting to sudden trade and policy disruptions—maintaining competitiveness and supply continuity for all stakeholders.

3. Scalability and Time-to-Market Risks

Scheduling/Demand Fluctuations: Qualified manufacturing partners can effectively and efficiently manage fluctuation of OEM upside and downside production requirements while mitigating adverse outcomes to customers.

Faster Launch Cycles: Automated processes, focused expertise, and dedicated production lines significantly accelerate time-to-market.

4. Cost and Resource Risks

Eliminating Fixed Costs: OEMs can avoid capital expenditures for specialized polishing, fiber testing, and validation equipment, by collaborating with qualified manufacturing partners.

Labor Specialization: Avoid costly personnel training and certifications. Skilled and highly trained technicians perform required intricate tasks.

5. Compliance and Continuity Risks

Regulatory Assurance: Qualified manufacturing partners maintain QMS excellence and required certifications (ISO 9001, ISO 13485, IPC, ITAR, etc.), support serialization requirements, and archive documentation for traceability, ensuring compliance in regulated markets such as medical and defense.

Risk Diversification: Qualified manufacturing partners with multi-site production mitigate single-point manufacturing failures and supply chain ruptures.

Risk Reduction Framework Summary

| Risk Type | How Outsourcing Mitigates Risks | Outcome for OEMs |

|---|---|---|

| Technical/Precision Failures | State-of-the art equipment; precision alignment; digital end-face inspection; rigorous end-to-end testing & validation | Elimination of failures; increased efficiency and yield; ensures reliable performance |

| Supply Chain Problems and Delays | Enhanced supply chain and component inventory management; increased flexibility, multi-region sourcing; economies of scale/contract pricing; tariff mitigation | Uninterrupted production; flexibility; cost stability |

| Demand Volatility | Scalable capacity; upside and downside demand management | Inventory management; faster response to market shifts, scale production as needed |

| Compliance Failure | Certified QMS; skilled/trained technicians; comprehensive process documentation & validated manufacturing processes; rigorous testing/validation protocols | Audit-ready QMS, processes, and products; faster approvals |

| Cost Overruns | No tooling/CAPEX; labor efficiency; economies of scale | Lower costs; freed capital |

Addressing Your Risks

Agility Tech’s fiber optic solutions directly address these risks through:

- Design for Manufacturability (DFM): Early collaboration to optimize designs for compatibility, functionality, manufacturability, cost, quality, and scalability.

- Multi-Site Resilience: Production flexibility across North America and off-shore facilities. Agility Tech offers its customers essential flexibility and options—quickly adapting to sudden trade and policy disruptions—maintaining competitiveness and supply continuity for all stakeholders.

- Lifecycle Management: Management of component obsolescence and alternative component support.

Bottom Line: Outsourcing transforms fiber optic production from a high-risk, resource-and-CapEx-intensive endeavor into a streamlined, predictable, and reliable high-value partnership—freeing OEMs to innovate while ensuring quality, compliance, and on-time delivery.

To learn more about how we mitigate OEM risks, click here.

Fiber Optic Assembly Outsourcing—OEM Pain Points

1. Alignment & Precision Challenges

- Sub-micron core-to-core alignment is critical; even a 10th of a micron misalignment can cause major signal loss.

- Inefficient and inadequate processes and protocols can introduce variability and high failure rates, especially in multi-fiber or polarization-maintaining assemblies.

2. Process Consistency & Quality Control

- Fiber optic assemblies require precise manufacturing processes and robust testing and inspection protocols to ensure consistent performance and reliability.

- High failure rates from misalignment or insufficient process controls can decrease efficiency, drive up costs, and delay time-to-market.

3. Supply Chain and Component Availability

- Component obsolescence and inadequate supply chain management can disrupt production and increase lead times and costs, especially for specialized connectors and materials.

4. Lack of Standardization

- The fiber optic industry’s evolving standards and diverse device designs complicate automation and increase the risk of incompatibility or rework.

5. Communication & Engineering Support

- OEMs need a specialized manufacturing partner who can provide design-for-manufacturability (DFM) feedback, rapid prototyping, and transparent project management—not just assembly labor.

Agility Tech Solutions: How We Address OEM Needs

1. Advanced Processing & Alignment

- We leverage our QMS excellence, expertise, commitment to DFM collaboration and process enhancement, specialized capital equipment/assets, and our highly skilled technicians to achieve sub-micron alignment and repeatable quality, even for the most complex fiber optic assemblies.

- Rigorous process controls and protocols ensure optimal optical performance and reliability.

2. Comprehensive Testing & Quality Assurance

- Comprehensive end-face inspection, insertion/return loss testing, and environmental validation to meet or exceed industry standards.

- Additional testing such as Optical Time Domain Reflectometer (OTDR) testing is incorporated as required to meet specific testing and validation objectives.

- We support serialization, traceability, and documentation archiving for regulated markets such as medical and defense.

3. Flexible, Scalable Manufacturing

- With North America and off-shore operations, we can scale production to meet your volume and cost objectives while mitigating tariff and supply chain risks, utilizing our extensive geographic diversification and multi-site manufacturing presence and extensive global supply chain infrastructure to effectuate competitive advantage for our customers. Our manufacturing capabilities in these strategic regions provide cost efficiency and geographic risk management. Read more about this here.

- Our proactive obsolescence management and vast network of strategic suppliers help ensure component availability and long-term support.

4. Engineering & DFM Support

- Our engineers collaborate with your team from concept through production and beyond, offering DFM input, rapid prototyping, and value engineering to optimize performance and manufacturability.

- We support a wide range of applications, from standard patch cords to highly specialized, custom fiber assemblies.

5.Transparency & Project Management

- Our dedicated project managers ensure clear communication, rapid response to design changes, and on-time delivery.

- We support the provision of comprehensive documentation/drawings as needed, and provide a single point of contact for all your fiber optic assembly needs.

Why Choose Agility Tech?

Proven Experience

Decades of fiber optic assembly expertise and a track record of excellence and distinguished OEM partnerships.

Full-Service Support

From DFM and prototyping to NPI support, expert supply chain management, scalable production, rigorous testing, and lifecycle management.

Quality & Compliance

QMS excellence, advanced testing, comprehensive protocols, and robust documentation and traceability for regulated industries.

Scalable, Resilient Supply Chain

Extensive global supply chain infrastructure; North America and off-shore operations optimize cost, lead time, logistics, and mitigation of tariff exposure.

Collaborative Partnership

Transparent communication, engineering support, and a commitment to your company’s success.

Leveraging Our Core Strengths

We exploit our multi-site agility, ensuring business continuity and effective cost control. Through leveraging our strategic supply chain relationships, bundled sourcing, our advanced automation and production capabilities, and inter-operational coordination and cooperation across global sites, we achieve economies of scale, delivering significant cost savings.

Quality assurance is realized through our ongoing commitment to and maintenance of requisite certifications, QMS excellence, standardized processes and dedicated quality control, which ensures consistent results, regardless of production location. Additionally, Agility Tech is committed to sustainability, employing lean manufacturing practices and regional sourcing to reduce waste and carbon footprint, proudly supporting the Environmental, Social, and Governance (ESG) goals of our customers.

Proven commitment and execution:

- Multi-Site Agility

- Automation

- Cost Efficiency

- Quality Assurance

- Synergistic Vertical Integration

- Sustainability

- BOM Management

- Tariff Resiliency

Our Partnership Ethos

At Agility Tech, we know that the strongest partnerships go beyond transactions—they’re built on clear communication, mutual respect, and a shared drive for excellence and success. Our Partnership Ethos checklist is designed to help OEMs collaborate with us in ways that push beyond the basics. When we both lean into this ethos, we can:

• Optimize designs • Streamline production • Manage risks • Accelerate innovation

Together, we’ll unlock superior quality, cost efficiency, and faster time-to-market.

This checklist is more than a tool—it’s a roadmap for transparency, agility, and continuous improvement at every stage of your fiber optics sourcing journey. We talk about it more on this page with EMS projects, but here’s the quick checklist:

- 1. Establish Clear Communication Channels

- 2. Share Complete and Accurate Documentation

- 3. Prioritize Design for Manufacturability (DFM)

- 4. Align on Technical Capabilities and Certifications

- 5. Collaborate on Supply Chain Strategies

- 6. Plan for Change Management

- 7. Focus on Quality and Compliance

- 8. Build in Flexibility and Risk Management

- 9. Evaluate Total Cost and Value

- 10. Foster a Collaborative, Problem-Solving Culture

Choose a partner who is proactive, eager to innovate,

and committed to continuous improvement and mutual success.

The Right Alignment—Meeting Your Current & Future Needs

Custom turnkey electro-mechanical assembly, electronic box, unit, UL508A control panel manufacture, custom cable assemblies & wire harnesses, molded cable assemblies, fiber optic assemblies, PCBAs, low pressure molding, precision metal fabrication & machining, and more—from product development, DFM and DFx, NPI, through to all phases of fully scalable global production—we’ve got you covered. Our adherence to the right strategic certifications, ISO 9001, ISO 13485, UL/CSA, UL508A, IPC, J-STD-001 Soldering, RoHS and Reach compliance, and S20.20 ESD compliance, firmware/software installation, and comprehensive validation and functional testing capabilities ensure compliance with all of your specifications.

We’re Ready to Start—Are You?

Contact us today to discuss your fiber optic assembly requirements. As you can see, we have vast capabilities and can effectively and efficiently meet your needs.

Whether you need a standard solution or a custom-engineered assembly, our team is ready to help you achieve precision, performance, and peace of mind at every stage of your product lifecycle. Let’s connect!

Agility Tech – Where Challenges Become Solutions