Monitor Your Steam Boilers in Your Brewery

Protect Your Brewery from Unexpected Downtime

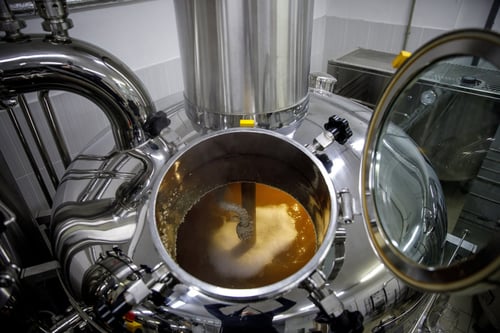

Steam boilers are a fundamental component of the brewing process, providing heat and steam required for various stages of brewing. Their efficient heat transfer, temperature control, and sanitation capabilities contribute to the production of high-quality beer. Moreover, the reliability, scalability, and energy efficiency of steam boilers are essential for maintaining uninterrupted brewing operations and promoting a sustainable brewing industry. Breweries that prioritize the proper functioning and maintenance of their steam boilers are better equipped to meet the demands of the market and deliver consistent, flavorful beers to their customers.

contribute to the production of high-quality beer. Moreover, the reliability, scalability, and energy efficiency of steam boilers are essential for maintaining uninterrupted brewing operations and promoting a sustainable brewing industry. Breweries that prioritize the proper functioning and maintenance of their steam boilers are better equipped to meet the demands of the market and deliver consistent, flavorful beers to their customers.

Understanding the Vitality of Steam Boilers in Brewing

The brewing process involves several key steps, such as mashing, boiling, fermentation, conditioning, and packaging. Each of these steps demands precise control and optimization to produce high-quality beer consistently.

At the heart of the brewing process, steam boilers are specifically designed to generate steam, which is utilized for various applications in brewing. Steam is a versatile and efficient medium for heating, boiling, sterilizing, and maintaining precise temperatures throughout the brewing process. The availability of a reliable and well-functioning steam boiler is crucial for breweries to produce consistent, high-quality beer that meets the desired flavor profiles and characteristics.

Heat Transfer and Energy Efficiency

One of the primary functions of steam boilers is efficient heat transfer. Heat energy produced by the boiler is used to heat and cook the brewing ingredients, such as water and malt, during mashing and boiling stages. This process facilitates the extraction of flavors and other essential compounds from the ingredients, influencing the taste, aroma, and overall quality of the beer.

Energy efficiency is a crucial consideration for modern breweries, both for cost savings and environmental sustainability. Steam boilers are engineered to maximize energy efficiency, converting the energy input into steam with minimal wastage. This not only reduces operational costs but also minimizes greenhouse gas emissions, promoting a more sustainable and eco-friendly brewing industry.

Temperature Control and Consistency

Steam boilers provide breweries with a reliable heat source that can be finely regulated to maintain specific temperatures for mashing, boiling, fermentation, and other critical stages.

Precise temperature control of this process is paramount throughout brewing—it is necessary for proper flavor development, enzymatic reactions, and yeast activity.

Maintaining precise and consistent temperatures during the brewing process is essential for producing high-quality beer with consistent flavors and characteristics. Controlling this allows for desired flavor profiles and characteristics of the final product, creating repeatable production of each brew.

Sterilization and Sanitation with Steam Boilers

Downtime = blown margins. That’s costly time, money, and resources for any operation, especially smaller breweries. Maintaining a clean and sanitary production line is essential to prevent contamination and ensure the quality and safety of the final product. Steam boilers play a vital role in the sterilization and sanitation processes within the brewery.

Steam can eliminate microorganisms, bacteria, and wild yeast that could otherwise taint an entire production run—from the fermentation vessels and kegs to piping, and peripheral surfaces.

Reliability and Reducing Downtime

Unplanned downtime has many faces and consequences: financial loss, brew process disruption, production delays, batch losses, and impact on brand reputation, making steam boiler operation one of many pivotal reliable operations in a brew house.

By conducting routine inspections, performing regular maintenance, and adhering to industry best practices, potential issues can be detected early, enabling prompt repairs or replacements. Embracing a proactive approach to boiler maintenance diminishes the likelihood of breakdowns, leading to heightened operational efficiency and minimized costly interruptions during the brewing process.

Scaling Up and Flexibility

As breweries grow their operations or venture into innovative recipes, the significance of their steam boilers’ capacity and adaptability rises exponentially. Steam boilers provide breweries with the remarkable capability to expand production while maintaining quality or consistency.

With a well-designed steam boiler system, breweries can effortlessly modify steam production to accommodate larger batch sizes or meet surging demand. The versatile nature of steam boilers ensures efficient and dependable heat transfer across various brewing volumes, empowering breweries to meet market demands while exploring exciting opportunities for further expansion.

Energy Efficiency and Process Control with Automation

Energy efficiency is a key consideration for breweries seeking to optimize their operations. Steam boilers are designed to be highly efficient in converting fuel into steam. The efficient use of energy helps breweries minimize operational costs and reduce their environmental impact.

In addition to energy efficiency, process control is essential for achieving consistent and repeatable results in brewing. Advanced systemic automation can regulate steam production, pressure, and temperature, ensuring consistency in products and enabling scalability and overall operational flexibility (think different varieties of beer with their own set of brewing parameters) without compromising quality.

Maintaining and Optimizing Automation Control of Your Brewery

Monitoring and maintaining steam boilers in breweries are essential steps to safeguard against unexpected downtime and ensure the seamless production of high-quality beer. The vitality of steam boilers in the brewing process cannot be overstated, as they provide efficient heat transfer, precise temperature control, and effective sterilization and sanitation capabilities. Energy efficiency and process control further optimize brewing operations, enabling breweries to reduce costs and minimize their environmental footprint.

Causes of Sporadic Steam Boiler Failures

- Poor maintenance and neglected inspections

- Mechanical wear and tear

- Incorrect operation and human error

- Water quality issues

- Age and equipment obsolescence

Monitoring Steam Boilers to Prevent Unexpected Downtime

- Real-time data acquisition and analysis

- Remote monitoring and alert systems

- Condition monitoring techniques

- Integration with maintenance management systems

- Continuous improvement and data-driven decision making

Implementing Preventative Maintenance Measures

- Establishing a maintenance schedule

- Conducting boiler efficiency tests

- Implementing component replacement programs

- Training and education for boiler operators

- Documenting maintenance activities

- Continuous evaluation and optimization

- BrewOps Solutions

How BrewOps Software Assists in Monitoring Steam Boilers

- Real-time monitoring and alerts

- Historical data analysis

- Remote monitoring capabilities

- Data integration and analytics

- Reporting and documentation

Flexible, Reliable Brewery Automation Control at Your Fingertips

By embracing automation and advanced process control, breweries can ensure consistent product quality, streamline operations, and optimize energy usage. Ultimately, investing in the proper care and management of steam boilers not only protects breweries from costly downtime, it also supports your long-term success in the competitive brewing landscape.

Contact us today to find out how we can help you achieve the full potential of your production capabilities, assets, and facilities management—we’ll introduce you to a BrewOps by Preddio expert and fast-track your project.